| Home |

| Email John |

| Last update

12/09/2010

|

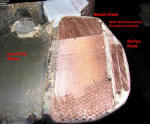

400 HP DC Motor

Custom Search

This motor is a compound wound 600 VDC, 1800 RPM unit. It is fairly old and some of the design techniques are obsolete. Nonetheless the construction is typical and interesting. This also shows what is necessary to produce 400 HP continuously and reliably.

The photo to the upper left shows Jerry Brown of Jerry's Electric Motor

Service (423 472-5959) loading the repaired motor onto his delivery truck.

Jerry's has a service area within about a hundred mile radius of Cleveland.

If you're within that radius I highly recommend their services.